Key players in the denim industry are choosing to use technology from the Swedish firm Polygiene® as they look to extend the life of their products.

As denim brands and manufacturers search for new ways to reduce their environmental impact, many are not only looking at how to minimise emissions and resource use, but also at how to make their products last longer.

This helps meet changing consumer expectations, which have been significantly influenced over the last year.

In a poll carried out by McKinsey & Company in April 2020, two-thirds of surveyed consumers said it has become even more important to limit impacts on climate change, while 88% of respondents believed more attention should be paid to reducing pollution.

The poll of more than 2,000 UK and German consumers also found that as a result of the pandemic, 65% of respondents were planning to purchase more durable fashion items, with 71% planning to keep the items they already have for longer. Additionally, 57% of respondents said they were willing to repair items to prolong usage.

Environmental impact

One particularly effective, but very simple way for consumers to extend the life of their clothes, such as denim jeans, is by washing them less frequently. A number of studies have found that consumers are responsible for large parts of the environmental impact of a garment during its life cycle, primarily due to their consumption and laundry habits.

The fewer times a product goes through the laundry, the longer it will last. And doing less washing also saves energy and water, as well as time and money.

Technology from the Swedish firm Polygiene has been developed to help brands and consumers make this happen.

Technology from the Swedish firm Polygiene has been developed to help brands and consumers make this happen.

Polygiene’s Stays Fresh technologies allows consumers to significantly reduce the number of times they wash a product by controlling odor in textiles – to, quite simply, wear more and wash less.

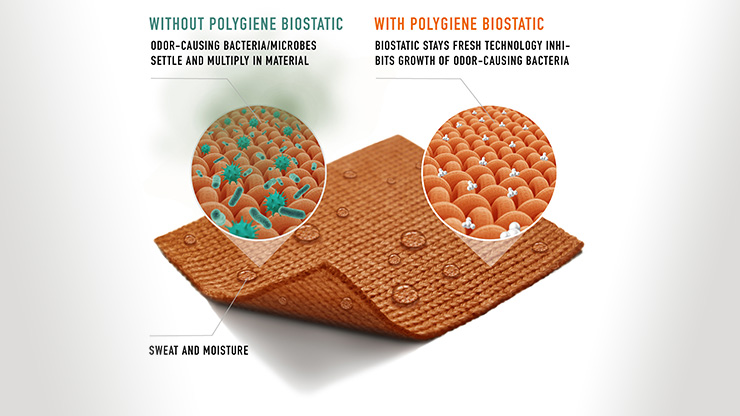

Polygiene BioStatic technology is an antimicrobial technology that inhibits and guards against the growth of odors from microbes such as bacteria and fungus. As a result, any product treated with this technology will stay fresh and hygienic for longer, so it is not discarded prematurely due to odor. It can be used several times before washing and can be washed at lower temperatures.

The treatment, which is bluesign® and Oeko-Tex® Eco Passport approved, is effective for the lifetime of the product.

Adoption by key denim players

Polygiene BioStatic technology has been widely used by sports and outdoor brands, and over recent years this has also led to growing interest among lifestyle apparel brands. In all, more than 200 global premium brands have now chosen to use Polygiene technologies with their products.

This includes a growing number from the denim sector, with UK label Hiut Denim among the latest. The company was set up in 2012 in the town of Cardigan in Wales, a place with a rich heritage of denim production. It is committed to producing jeans of exceptional quality and makes just 150 pairs a week. The brand shot to prominence in 2018 when Meghan Markle was spotted in a black pair of Hiut jeans, creating a big buzz and a backorder waiting list for three months.

The company chose to use Polygiene’s BioStatic technology to help their jeans stand the test of time.

The company chose to use Polygiene’s BioStatic technology to help their jeans stand the test of time.

“We want to be as low impact as possible, and producing a stretch jean comes with impact,” says Clare Hieatt, co-founder of Hiut Denim. “To help reduce this and improve the product, we have chosen to work with Polygiene. Their technologies helps the customer wear more and wash less.”

Polygiene BioStatic is particularly effective with skinny jeans. That’s because this type of denim contains a high percentage of stretch fibre. Over time, the jeans tend to wear down because bacteria eat the substrates in the fibre, reducing the stretch effect.

However, Polygiene BioStatic preserves the stretch as it keeps them bacteria free, so the technology helps increase the life and performance of the jeans.

Gains from washing less

Another key denim industry player working with Polygiene is Naveena Denim Mills. This partnership was officially announced at the virtual denim industry event Kingpins24 Amsterdam in April 2021.

Naveena, established in Karachi, Pakistan in 2005, manufactures premium yarn and denim fabrics. The latest ranges from Naveena include its new Stays Fresh collection, powered by Polygiene BioStatic technology.

The news has generated much positive feedback and enthusiasm within the industry, as well as from denim aficionados who try to wash their jeans as little as possible. This is to ensure that the deep blue from the indigo plant that is used in denim stays true, and due to the particular way, a pair of ‘raw’ jeans breaks in over a period of time – something laundering too often will ruin.

With studies showing that in the US people own on average seven pairs of jeans1, Naveena is also highlighting the major environmental gains of washing less.

To help meet the growing demand it is experiencing, Polygiene has also expanded its range of technologies, and these treatments are also being adopted by leading names in the denim industry.

Diesel launched new denim styles featuring Polygiene Stays Fresh Technologies OdorCrunch and Polygiene ViralOff technologies in its Spring/Summer 2021 collection.

Polygiene OdorCrunch, launched in 2019, is an odor control based on a sand and water solution. It deals with environmental odors such as cooking fumes and cigarette smoke that tend to stick to our garments. Once the odor molecules have stuck to the modified silica particles, they will be crunched and cracked to odorless molecules and the odor is eliminated for the lifetime of the garment.

Polygiene ViralOff was launched in 2020 in response to the growing demand for antimicrobial performance. This technology is a treatment of textiles and other products that reduces microbes by over 99% on the tested material*. To develop this technology, Polygiene returned to its roots – the company started in the healthcare sector in 2004 during the battle against SARS.

Diesel applied a combination of Polygiene OdorCrunch and ViralOff treatments to a selection of denim models during the final production stages. The brand also features this combination technology in some of its latest apparel collections.

“This exclusive combination reduces the microbes on the surface of the fabric, and effectively breaks down and eliminates odors,” Diesel states.

Tackling the challenges

Tackling the challenges

As denim brands and manufacturers look to progress towards greater sustainability, Polygiene is aiming to support companies on that journey. Recent initiatives include joining the ZDHC Roadmap to Zero programme alongside its partners.

Polygiene’s raison d'être mirrors much of the denim industry as a whole as brands and manufacturers focus on creating products with reduced impact, greater durability and an extended life.

One leading denim brand has said that the entire lifecycle of a pair of its jeans equates to 33.4 kg of CO2 in emissions – the same as driving 111 km in a car2. This adds to concerns about water and chemical use, with estimates suggesting that current production methods for jeans use more water in a year than the US has drinking water. Similarly, it takes about three and a half times more chemicals than cotton by weight to make, dye and care for a pair of jeans3.

Brands and manufacturers are ramping up their efforts to tackle these challenges. But the concerns about production methods are being compounded by worries over the microfibers being released from denim jeans. A study4 released in September 2020 found that around 50,000 microfibres were released from the surface of jeans every time they were cleaned.

This underlines the importance of not only ensuring denim garments maintain their performance for longer, but also that they can be washed less frequently. Both minimizing the need for users to consume more jeans in the future.

As Polygiene’s technology helps resolve this issue, Kingpins’ founder and CEO, Andrew Olah, believes the Swedish firm can help transform the denim industry’s reputation. “The ability to confidently remove the need to wash your jeans, unless you spill a bowl of pasta on your lap, with a technology like Polygiene Stays Fresh is a game changer,” he says.

“We all know how we shouldn’t wash our jeans in order to break them in correctly and in addition the environmental impact that the end-consumer has on washing a pair of jeans is well documented. The benefits this technology brings to the denim industry is really positive in my opinion.”

*Polygiene ViralOffTM does not prevent diseases but protects the treated material. It is tested on certain materials according to ISO18184 on SARS-CoV-2, H3N2, H1N1, with over 99% reduction within 2 hours, in the product or the material.

1 [source - textilefocus.com/fact-jeans/]

2 [source - Blue jeans pollute water by releasing 50,000 microfibres per wash | New Scientist]

3 [source - Slide 1 (levistrauss.com) – see page 17]

4 [source - Make - Levi Strauss & Co: Levi Strauss & Co]