An Independent Analysis From

BluWin Limited Shows Incredible Savings of Up To

![]()

PROBLEM

- Traditional practices for denim garment washing uses hazardous chemicals, excessive amount of resources and multi-stage processing/handling.

- Innovation alone will not mitigate this, but a combination of advanced technology, with a clear service platform to support the industry is required.

SOLUTION

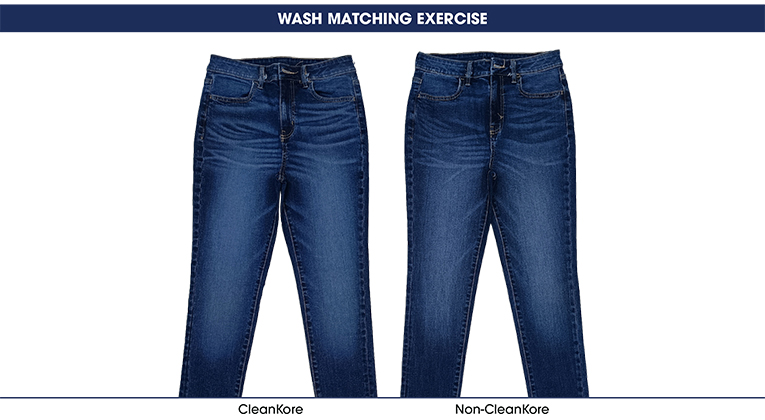

CleanKore, a business embedded in the denim industry, has leveraged these roadblocks to pioneer a full service platform, offering cost effective and sustainable solutions to the denim supply chain. Their patented technology starts at the denim mill, where they are changing how yarns are dyed by preventing unwanted dye penetration and protecting the natural whiteness of the yarn creating a ring dyed effect. Over 300 trials worldwide, have proven CleanKore works on all dye ranges, fabric types, and indigo and sulphur combinations. All without the need of any new equipment or special chemicals.

From there, the CleanKore team works with the garment manufacturer to convert traditional recipes to lean recipes, resulting in the elimination of Potassium Permanganate (PP) spray and reduction in water, chemicals, energy, time and carbon footprint. Software, such as EIM scores, always remain in the green zone as a result of the lean wash recipes.

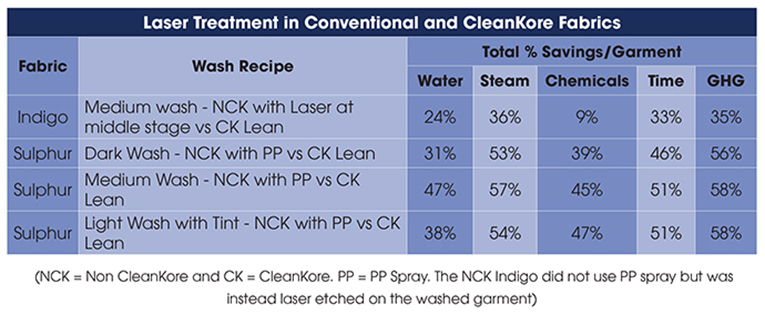

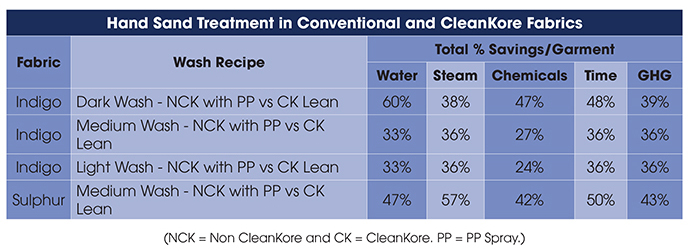

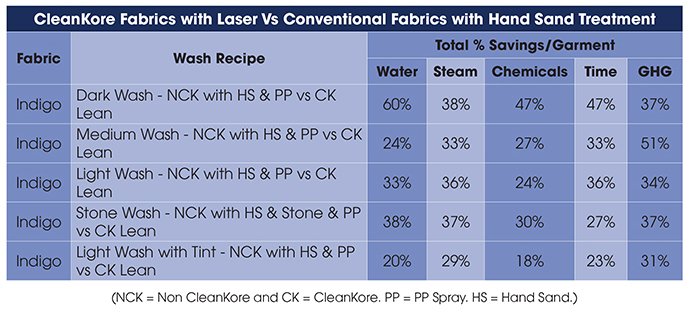

Dry processing typically consists of hand sanding with PP spray, laser with PP spray or laser on the washed garment. With CleanKore, hand sanding alone or laser etching on the unwashed garment can achieve the necessary brightness, without the need of any hazardous chemicals.

Michael Morrell, President/CEO at Freedom Denim Americas, said: “We’re always trying to push the envelope of sustainability, however, never at the cost of impacting the aesthetics. After conducting numerous CleanKore trials and now being in stores at Mens Wearhouse, the quality and look of the garment have never been impacted and in many cases looks better. Now that there’s mathematical data that has been verified to support the savings, it's a great story to share with the industry and we’re excited to play a role in this analysis.”

For sustainable solutions to truly be scalable, they can not negatively impact the cost. Mr. Ranjan Mahtani, Chairman, Epic Group and CleanKore partner said, “CleanKore technology offers a fantastic value proposition of significant sustainability benefits to our associates and the environment, without increasing cost.”

VALIDATION

CleanKore appointed BluWin Limited, leading subject matter experts, to provide professional assistance to conduct and validate the comparative savings associated with denim fabric manufacturing and subsequent modified garment washing at laundries using traditional vs CleanKore fabrics. The fabric studies was carried out at CleanKore licensees, Envoy Textiles, for the indigo shade and Freedom Denim for the sulphur black shade. The garment washing study was conducted at Mahmud washing plant.

CleanKore appointed BluWin Limited, leading subject matter experts, to provide professional assistance to conduct and validate the comparative savings associated with denim fabric manufacturing and subsequent modified garment washing at laundries using traditional vs CleanKore fabrics. The fabric studies was carried out at CleanKore licensees, Envoy Textiles, for the indigo shade and Freedom Denim for the sulphur black shade. The garment washing study was conducted at Mahmud washing plant.

For Tushar Tripathi, CEO of Envoy Textiles, the BluWin results verified his strong belief in CleanKore, “At Envoy, we believe in sustainability achievement with innovation and collaboration. The innovation should be scalable and most importantly, cost-effective. The BluWin analysis shows considerable resource savings at both mill and garment factories, along with a reduction of green house gases.”

METHODOLOGY

BluWin began their study visiting both denim mills, comparing the traditional dyeing vs CleanKore dyeing on both rope and slasher ranges with indigo and sulphur black. Resource savings were calculated throughout the entire process, from the beginning of the range to the end, analyzing each box. They then followed the fabric for garment washing. The traditional fabric in indigo and sulphur black went through standard wash recipes, while each CleanKore version was converted to their lean recipes. In total, 13 wash trials were used for this study with a sample machine and commercial chemicals.

Site visits occurred at all three factories and matching exercises were extensively reviewed for comparison and validation of the results. The net saving potential was analyzed and listed in terms of water, steam, chemicals, time and GHG (CO2 emissions) per garment. Commercially, the dry process for denim garments are being done by both laser and hand sanding. The BluWin analysis was carried out by both methods and the data is compared as per industry practices.

Nurul Islam, GM of Mahmud Washing saw the benefits of utilizing the CleanKore team’s experience to maximize results, “It is essential to explore alternative methods to reduce the environmental impact caused by our industry. CleanKore was invaluable teaching us environmentally friendly washing techniques, including different dyeing techniques to cutdown on overall timing, bleaching, elimination of PP spray, but most importantly, converting traditional recipes to lean recipes.”

The exciting results are below:

The results from this study show the robust saving potential by adopting CleanKore’s patented technology.

Summary - we are proud of demonstrating at a commercial level:

- Water Savings Up To 60%

- Steam Savings Up To 57%

- Chemical Savings Up To 47%

- Time Savings Up To 51%

- GHG Savings Up To 58%

Darryl Costin Jr, CEO of CleanKore, said “We had 3 main objectives for this report. One, to get our data verified by a third party, and BluWin is one of the best. Two, even though we strongly promote eliminating PP spray, our technology has many more benefits and offers substantial savings, regardless of a companies corporate sustainability initiatives and goals. And finally, to offer a sustainable and cost effective solution that will work in any denim mill in the world and at any garment manufacturer, regardless if they focus on laser or hand sanding.”

Special thanks to our CleanKore licensees and partners for their participation, along with BluWin for this first class report.

Please email us at info@cleankore.com and follow us on LinkedIn to learn more about our innovative solutions for the denim supply chain.