Washi Jeans: A labour of love

23/06/2021

Founder Hiro Yoshikawa spent many years working for brands and learning the art of denim making and jeans design, but wanted to bring something unique to his designs.

He chose to create the fabric using cotton and traditional Japanese washi paper, saying it adds properties including shape memory and is antibacterial – but which took many years to develop into a yarn that would work in denim.

Washi limited-edition jeans are made using over 15 different models of vintage sewing machine with in-house developed buttons. Each pair goes through more than 20 washes, taking several months, and using only recycled water.

The white selvedge paper fabric is woven on vintage Toyoda weaving machines with hand finishing in Okayama. Every 10cms, the mark on the fabric is a sign of the slow weaving process.

Learn more about the process, and listen to Mr Yoshikawa’s thoughts on the care that should go into making jeans, in his discussion with consultant Ikeme Eshemokhai in the latest edition of Inside Denim.

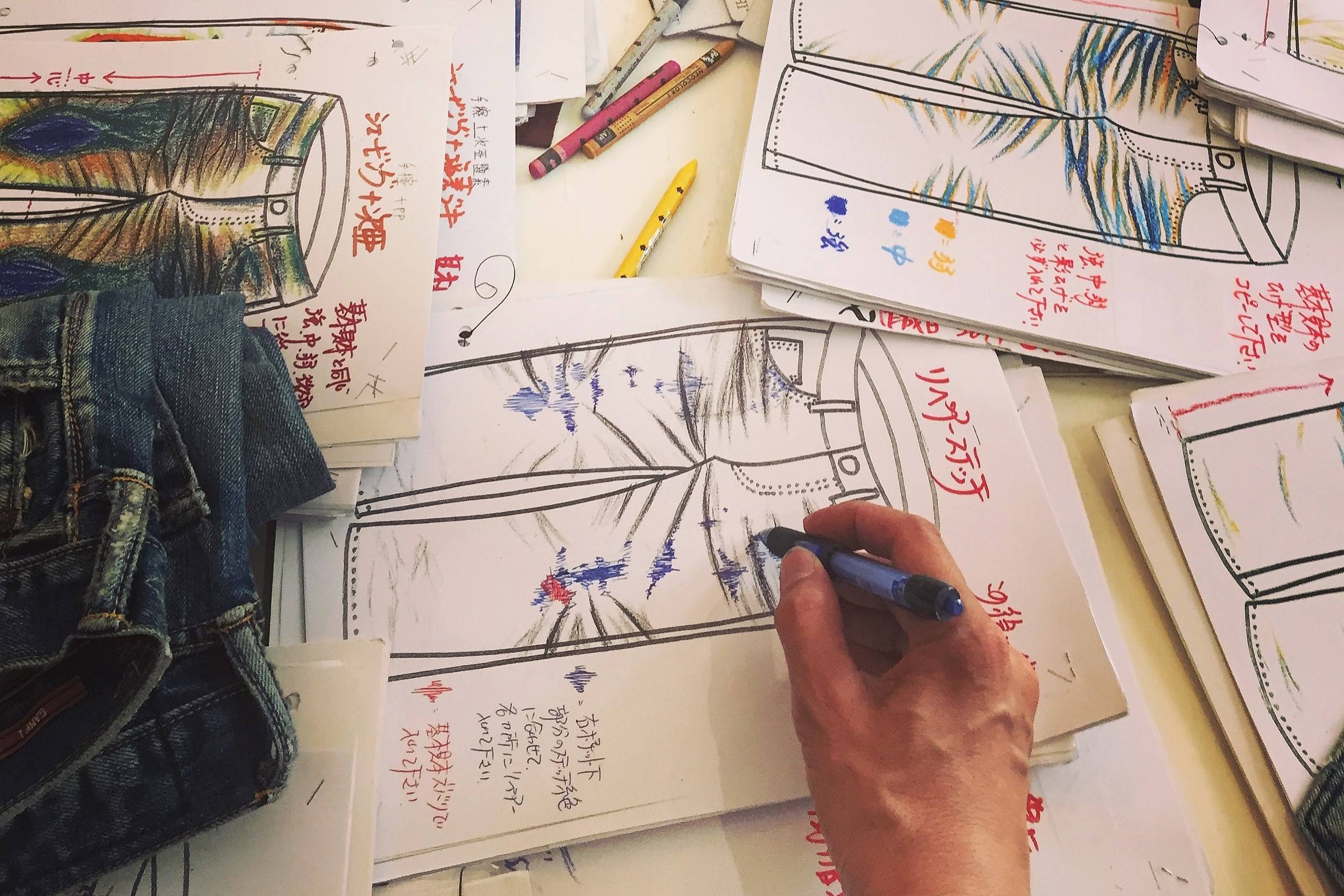

Image: Hiro and his designs. Credit: Washi Jeans