Textiles circularity pilot asks for denim brands to ‘walk the talk’

27/07/2021

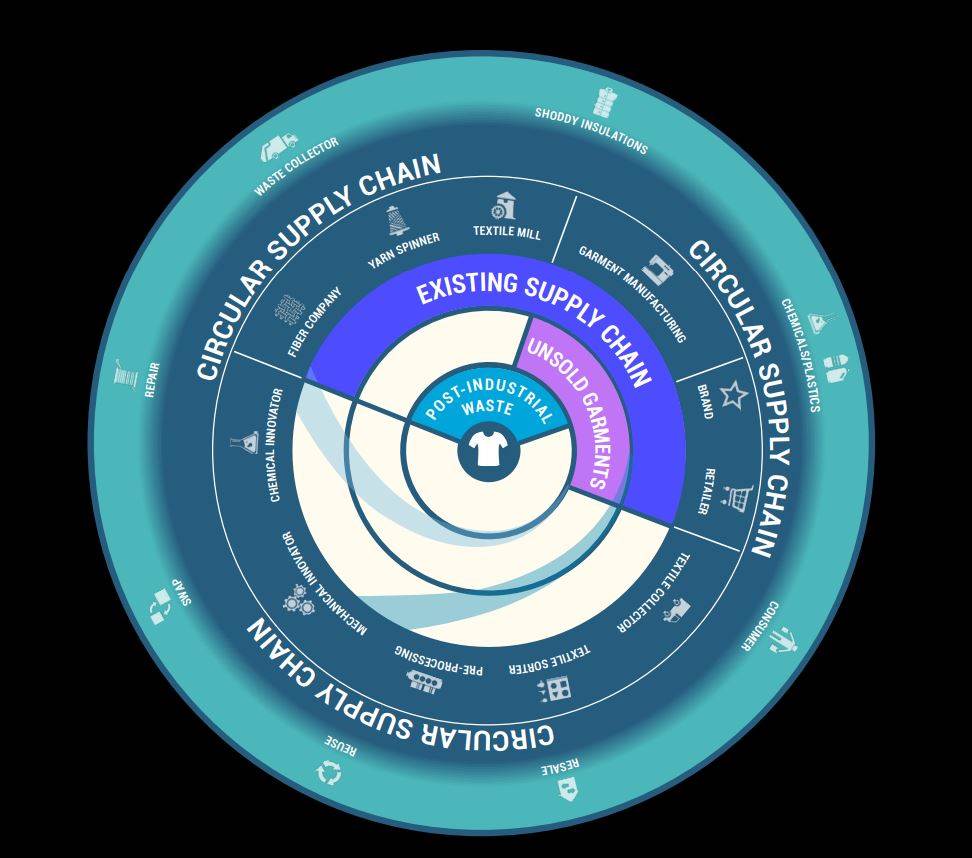

The Accelerating Circularity project will include participants along the supply chain, and is asking for more brands and retailers to take part to scale up the learnings.

The project aims to define highest-value use for collected materials as well as to establish a circular systems marketplace.

Lenzing’s head of business development for denim, Tricia Carey, is a director, alongside representatives from Walmart, VF, Eastman, Target and Gap, among others.

The project will look at the supply chain for garments including t-shirts, fleece and home textiles and will include various fibre blends as well as mechanical and chemical recycling.

Three denim garments will be “remade” as part of the trial. One will include jeans with 40% Refibra lyocell (partly recycled and made by Lenzing), 40% recycled cotton and 30% organic cotton.

For the Refibra denim, textile for the pulp is located in Alabama, rCotton is collected and processed in the south east of the US and organic cotton is grown in Texas. All fibre is shipped to Mississippi, where it is spun into yarn. Fabric and garments are made in California and shipped to US brands and retailers.

During a webinar to discuss the project, project leader Janel Twogood noted how many brands had made big commitments on reducing waste and becoming more circular. “But how will we meet all these commitments? The volume of fibre and textiles used far outstrips the recycling capabilities and the collection systems. We need investment, commercialisation and policy to make these things happen. Brands can walk the talk by joining this project, and it will help them meet their commitments and goals.”

She said while there are systems in place to collect, sort and reuse textiles, it has not been done in a coherent manner, involving all players in the chain. “We don’t need to invent new technology, we just need to think about how to realign it. We’ll achieve circularity when we shift the relationships between things.”

Next steps include creating tools that support scaling and replication, educating consumers, collecting data and developing sorting hierarchies.