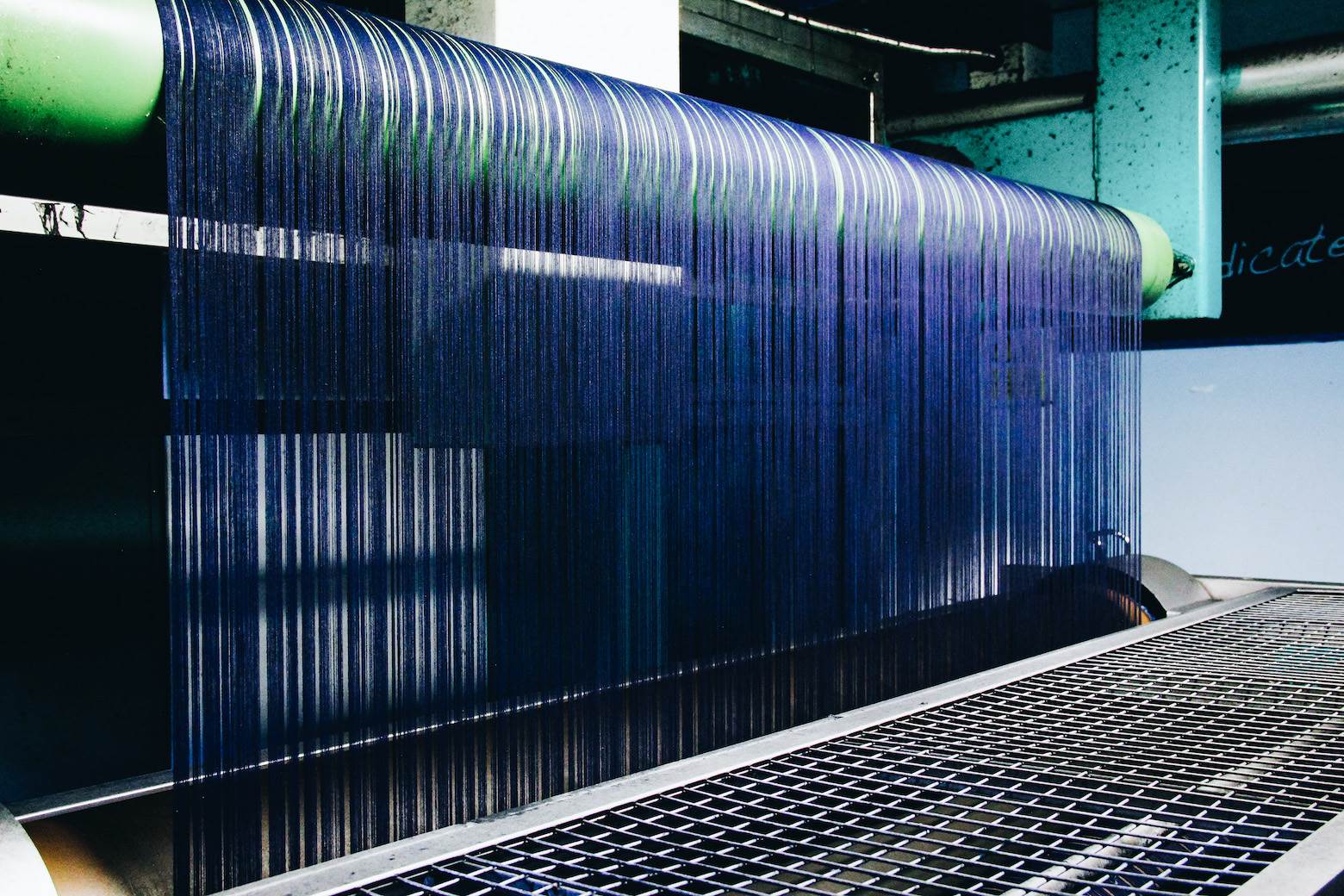

Truth Series takes a close look at indigo dyeing

08/07/2022

The talk looked into the challenges the industry faces with regards to dyeing and, true to its mission, sought to cut through some of the many misconceptions that surround indigo dyeing processes.

Water usage in indigo dyeing is one of many areas where the numbers that are propagated tend to conflate data from cotton growing with dyeing, as Kürsat Solmaz pointed out. “If we exclude water usage consumed by cotton farming, and focus only on the indigo warp dyeing process, 20 litres of water are used to dye one meter of fabric generally,” he said. A pair of jeans requires on average 1.25 m of fabric, which means that 25 litres of water are used per pair. But he pointed out that only the warp is dyed, making up half of the fabric, bringing the real number down to 10 litres per meter.

With regards to wastewater, Günther Wilder noted that dyeing is not the culprit it is made out to be. “The fixation rate of indigo is very high, around 97%, which means that only 3% of indigo dye is discharged into wastewater. Compared to the garment washing phase, the denim mills are not the ones doing the most harm,” he said.

What makes indigo so special, for Salli Deighton, is that no other dye ages so well. “It tells its own story and it is what makes blue jeans so special,” she said, insisting that “we need to bring back the love for indigo.” LaundRe is experimenting with ozone, enzymes and fake stones. She noted that combining ozone with new enzymes that activate the fading process now achieve better results. “We are understanding better the advantages that ozone can bring,” she said.

The talk also touched on ongoing research into printing, biotech and natural indigo. These may, in time, become mainstream solutions. “It took 15 to 20 years for the first synthetic indigo, developed 125 years ago, to reach industrial scale,” said Günther Wilder. A sign that indigo holds many future promises, but that we also need to be patient.

For more information on the promises of ozone, read our feature here.

For an overview of indigo’s history and heritage, see our feature here.

Image: warp dyeing at Isko in Turkey