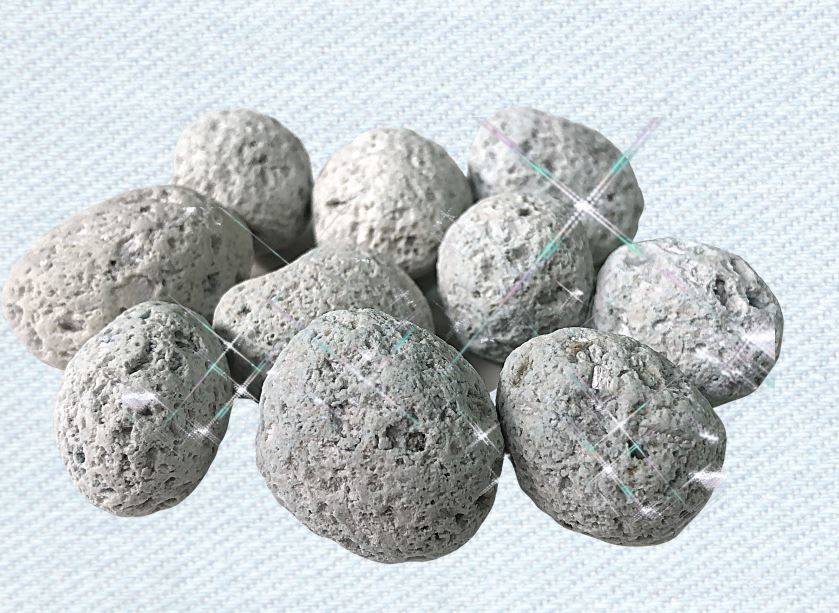

Durable pumice alternative upcycles waste stone from quarries

06/07/2021

Turkish company Baytech is behind the HMS (Hand Made Stone), which is made from 60% pumice dust, sealed with biodegradable polymers, which the company says offers similar abrasion to traditional stone but breaks down substantially less, meaning the waste sludge is almost eliminated and the stones last longer.

This can lead to savings in transportation, water, waste, time and energy, according to the company.

HMS was set up in 2016 by Yavuz Baykan, a former manager at a Turkish denim garment maker, who became frustrated with the vast amounts of pumice sludge that was difficult to dispose of and which he felt was damaging to the environment. After finding a lack of alternatives, he began to research an option that could combine the effectiveness of the stones but that would be more durable.

The company began by using the pumice waste from a denim laundry, but removing the impurities and drying the sludge took a long time and increased the cost, so the raw material is now sourced from Turkish quarries – finding a use for the waste from another industry while making the costs more competitive.

Beyza Baykan, Yavuz’s daughter and Baytech managing director, told Inside Denim: “With durability comes advantages such as reduced transportation and the CO2 savings associated with that. We estimate our stone is greater than 50 times more durable than the traditional stones - depending on the processes' parameters used and the technology - so that means a lot less shipping.

“The residue generated is reduced, so this results in time savings, as less time is spent getting rid of residue or loading stones. HMS stones also don’t need the chemicals that are normally associated with abrasion cycles.”

She added one of the big benefits is the water savings that can be generated: less water is needed, plus the rinsing stages are reduced because there is much less dust to wash off the garments.

Baytech (HMS) has worked with laundries in 20 countries over the past two years, using the feedback to improve the product, increasing the abrasion and durability. The company claims its tests now show that rather than the average 500g pumice that is used in a 60-minute abrasion cycle per garment, only around 15g of HMS is consumed.

Ms Baykan added: “The main pillars of HMS are high abrasion, durability, fabric strength – as the stones don’t affect the fabric like some chemicals – and speed. These have advantages for the designer, laundry, the consumer and environment.”

HMS has launched a marketing campaign, including blogs and social media hashtags, to try to tell the story to the end consumer. “If they are more knowledgeable about how denim is produced, how many chemicals are used and how it can be more sustainable, it will increase awareness,” said Ms Baykan. “If the end consumers don’t care, the brands won’t care and there won’t be demand for change and sustainable products. Younger people are so conscious about how we can help the environment, so that has inspired that element of our thinking.”

The company is shipping the stones to garment producers and processors including denim, non-denim and knits for trials, and is ready to scale up. “We are increasing our capacity to service the growing demand,” added Ms Baykan.

Photo credit: Baytech