Carrying on Miguel’s legacy: indigo report is start of wider project

The team behind Transformers Foundation’s latest report have explained how the project was the brainchild of its former technology lead, the late Miguel Sanchez, and that they hope it will help to provide some benchmark data into water use with indigo dyeing.

Published in late July, ‘A reference for water consumption during indigo dyeing’, was supported and coordinated by Rashid Iqbal from Naveena Denim NDL; Transformers’ Paolo Leidl, Andrew Olah, Emily Olah and Zennure Danisman, with the report written by Alden Wicker and illustrated by Sadia Rafique.

Speaking as part of a webinar to explain the findings, Mr Iqbal said: “In 2022, we discussed the idea that there were no references or benchmarks. Our dear friend Miguel really helped us set up the standards and parameters for this report.”

The report was born from a need to provide some real data and figures, to help educate and empower brands, and to help mills transparently compare their processes, explained Andrew Olah. The previous lack of information meant it has been difficult to determine if water figures were good or bad - especially if used as a percentage reduction, for example - so it could also help to counter greenwashing.

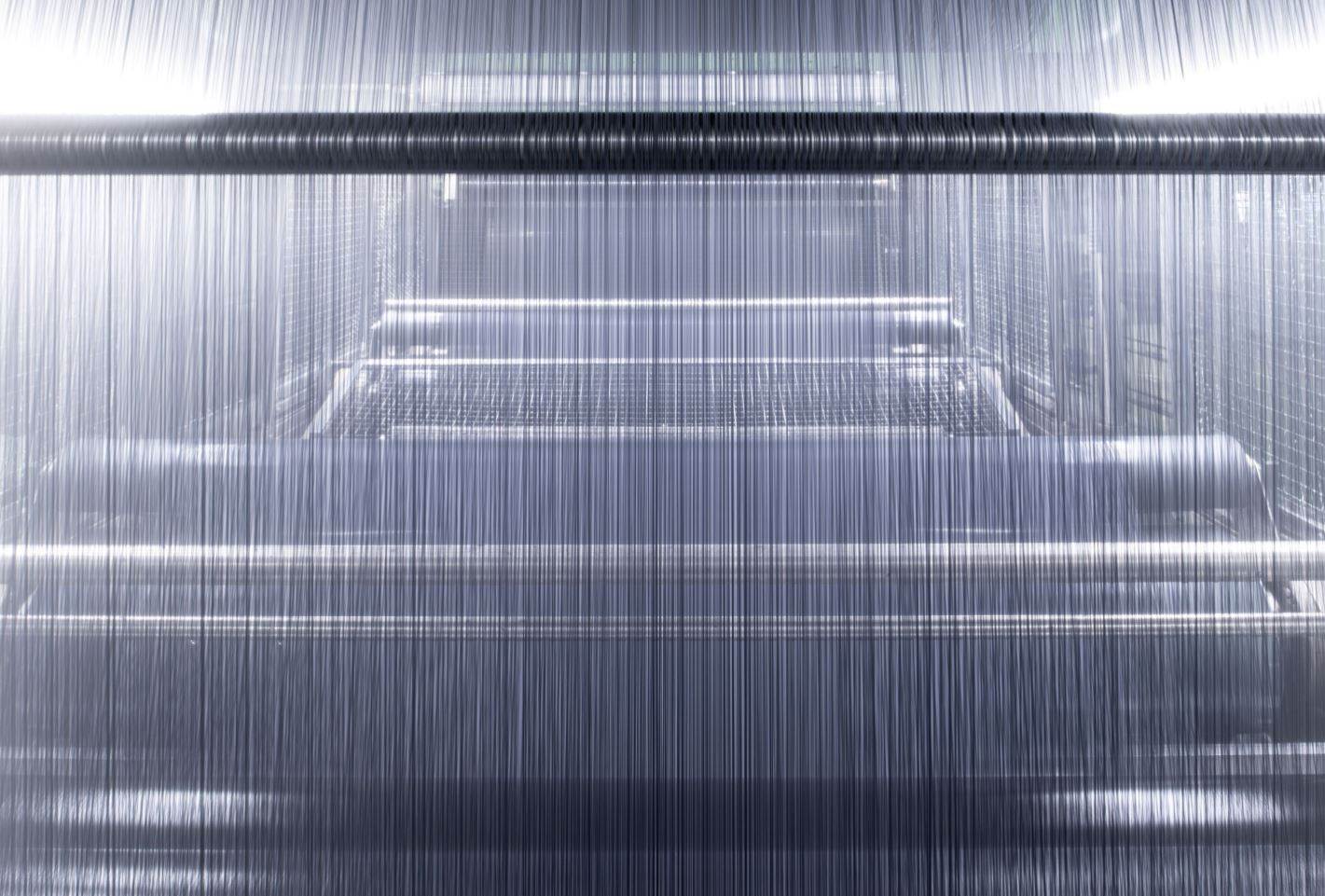

Mills NDL, Advance Denim, Diamond Denim, Candiani, Orta, Soorty, Crescent Bahuman as well as machinery companies Karl Mayer and Morrison, with DyStar and Bluesign, worked together to submit data from rope or slasher dye machines using a defined set of parameters.

Andrew Olah said: “These are a group of companies that compete, and yet they sat down with us and helped us to put together this information. This is what makes me proud to be part of this industry: the mills and machinery companies collaborate – they want to do the right thing.”

Overall, they found the average quantity of water used in the post washers ranges from 13 to 15 litres per kilogram for rope dyeing and 7 to 10 l/kg for slasher dyeing. A few exceptional cases demonstrated significantly lower usage, with minimum values recorded at 3.85l/kg for rope and 3.4l/kg for slasher.

The team stressed the aim was not to say one way was better than another, but only to gather real-time data. They also wanted to measure how much indigo was left in the wastewater.

Technical lead Paolo Leidl added the report has limitations, as it was necessary to work within certain boundaries for comparative figures, and does not take into account fixing agents or finishing, for example. “There are many parameters that can affect results, and the target of our study wasn’t to measure efficiency, but we thought it was important to show these values.”

There is more work to be done in the field of indigo recycling, he suggested, having worked for a mill 30 years ago that reused indigo from wastewater using membranes – but the technology was later deemed too expensive.

Andrew Olah added that often areas that are big denim manufacturers, such as Pakistan and Bangladesh, also have water scarcity issues, so using best practice in manufacturing is imperative to save the water for the people.

In the future, the team would like to investigate wastewater, indigo recycling, low impact dye technologies and finishing processes.